Building the most efficient digital freight network, eliminating billions of waste in trucking

Convoy News • Published on November 13, 2019

The inefficiencies in trucking are not new. For years, people have talked about empty miles, yet 35% of all miles are still driven empty. There is a shortage of drivers, yet detention and payment remain a hassle. Drivers spend an average of 2.5 hours loading or unloading at each stop. These issues eventually translate into higher prices and worse service for shippers.

The problem is that trucking has been viewed as a zero-sum game. In order for one party to do better, another has to do worse. The freight broker model hasn’t helped. As brokers get bigger, they don’t solve the industry’s inefficiencies. In many cases, they get less efficient with more people and more complexity. This is equally true for the digital broker model.

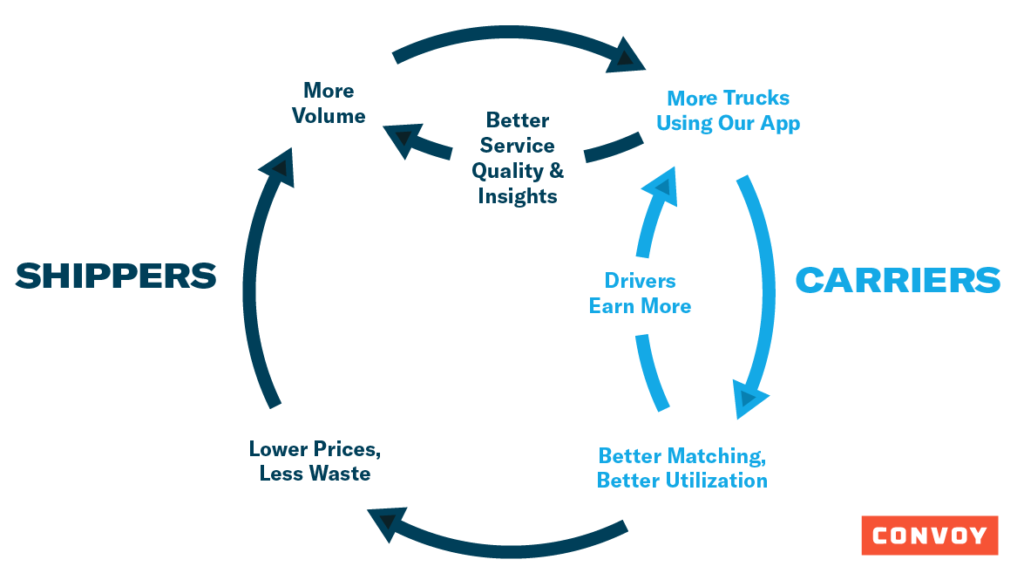

In 2015, Convoy saw an opportunity to fundamentally rewrite the economic model for trucking. Looking at the freight industry from the outside, it is apparent that there should be a network effect where the value for both shippers and carriers increases as more people participate in the marketplace. The trucking industry is fundamentally about matching the right driver to the right shipment.

This is what we have been working on for the past 4 years. Convoy’s digital freight network creates a flywheel that drives efficiency for both shippers and carriers. This flywheel is fueled by innovations like Automated Reloads, Convoy Go and Matching Automation. As more shippers join the network, drivers have better options, fewer empty miles and fewer wasted hours allowing them to earn more per day. As more carriers join the network, capacity increases and shippers see lower prices per mile and higher quality. In addition, as the network grows, insights emerge from the data that help shippers and carriers improve their businesses.

We’re excited about the progress we have made so far. But there is much more to do. Today, I am excited to announce $400M in additional funding co-lead by Generation Investment Management and T. Rowe Price Associates. This funding will allow us to substantially accelerate our rate of innovation and execute our vision.

Building a Digital Freight Network

In pursuing our vision, we’ve taken a different approach. The principle we have used to guide our decision-making is this: what does it take to make the flywheel to spin faster?

Automated Matching

Brokerage fees average about 20% with a high degree of variability between each load. A brokerage success is built around capturing the highest possible margin on each load booked. Brokers need to charge this fee because the work of the broker is traditionally manual and labor-intensive.

Matching is the heart of a network and shifting this from human-driven to a machine-driven process sets the foundation for all subsequent innovation. A digital freight network automates the matching of trucks to shipments, drastically reducing the cost structure and the time it takes to find the most efficient truck for every load.

Convoy is the only company to 100% automate the process of matching loads to trucks. With this milestone, we have largely eliminated the call-intensive model for finding the right truck across Convoy’s national network.

Routes not Shipments

Of all the problems in trucking, this one is the most classic computer and data science problem. A digital freight network automatically evaluates billions of load combinations to determine the ideal way to combine shipments. This results in not only less effort by truck drivers, but substantially more efficient routes increasing earnings for drivers.

Convoy’s Automated Reloads, which uses machine learning to group full-truckload shipments for carriers, is now exceeding 50% in top markets and is already yielding a 45% decrease in CO2 emissions from trucks running empty less often.

Open Access to Freight

There are about 3 million trucks and 1 million carriers in the US. To keep their trucks full, these carriers maintain relationships with multiple brokers attempting to get visibility into more loads. No matter how hard they try, most carriers see only a fraction of all available freight at any given time. Even worse, more than half of all freight is drop-and-hook shipments, which traditionally excludes the majority of carriers who do not have assets required for these operations.

Being able to match any truck to any shipment creates a more efficient network. A digital freight network democratizes access to freight, ensuring all loads are available to all carriers at all times, so the most efficient option is always available.

Convoy Go offers drop shipments to millions of drivers across the nation supported by a large and expanding Convoy trailer pool giving carriers access to billions of dollars in new shipments which can increase their productivity up to 50%.

Real-time Planning

Today, scheduling loads and planning the carrier’s week are static operations set ahead of time. But the real world is dynamic with changing weather, traffic, breakdowns, varying hours of service, and unpredictable loading times. A delay at one facility can lead a carrier to miss their next load.

A digital freight network is constantly looking for ways to re-optimize. It automatically adjusts for changing conditions and unforeseen events to maximize efficiency and prevent waste. It is resilient to even the most unusual events.

Convoy direct-from-shipper helps shippers get high-quality coverage of loads even in difficult situations. When Hurricane Dorian struck in August, direct-from-shipper loads accounted for 75% of the spot shipments delivered in Florida through the Convoy network.

Leading the Transformation

Over the past 4 years, we have been investing in a different vision for the trucking industry. We are excited to lead a transformation in freight with the most efficient digital freight network in the industry.

This experience has been validated by the feedback and relationship that we have with carriers and shippers. Many of the nation’s biggest shippers including Anheuser-Busch, The Procter & Gamble Company, Wayfair, CHEP, Land O’ Lakes, Niagara, Ardagh, and Unilever are now working with Convoy.

Our commitment to reducing the waste of trucking underpins everything we do at Convoy. We believe this is a mission worth chasing, and it will have a lasting impact on our economy, the trucking industry, and more importantly, our planet.

— Ziad Ismail, Chief Product Officer at Convoy