Case study: From Sheer Frustration to High Satisfaction with Convoy

Shippers • Published on July 13, 2018

Some companies think they have it tough when setting up and orchestrating the delivery networks that shuttle their products from point of origin to end customer, but J.R. Butler faces some especially high hurdles. A commercial glazing contractor in Denver, the company specializes in vertical and sloped glazing, with an emphasis on design-build, fabrication, and installation.

A key aspect of J.R. Butler’s business involves pre-manufactured windows that significantly cut down on the hours it takes to install its products out in the field. Historically, most of those installs happened in and around the Greater Denver area. However, over the last few years, the company has been expanding to other areas of Colorado and into other states (e.g., Oklahoma and Texas)—an effort that’s extended its supply chain and pushed it to rethink its freight and transportation management strategies.

“For our Denver jobs, we hauled our products using flatbeds and then loaded and unloaded the windows with tower cranes,” says David Muench, assistant project manager. When working on a large project in Austin, the company reassessed its shipping expenditures and didn’t like what it saw. Not only was J.R. Butler spending a lot of money on shipping, but it was also experienced a high level of project damage.

“We were going through trailer tarps like crazy; it was super frustrating,” David explains. “We also had a couple of trailers of material get completely destroyed from the tarps buffeting the glass.”

“Let’s Give it a Whirl”

Eager to find a better, safer, and more efficient transportation option, J.R. Butler completed a cost-benefit analysis and decided that dry vans would be a better option for its long-haul shipments. With no experience using “live loads,” the company would load its trailers, store them out in its yard, and then ship them out of state as needed.

“We started looking at live loading and decided, ‘We’re going to try dry vans; let’s give it a whirl,” says David, whose team over the next three to six months spent time rebuilding the firm’s crating department and installing dock levelers in order to ensure easy access to its dock doors. J.R. Butler then started working with a local provider of dry van transportation solutions.

“They were pretty frustrating to deal with,” says David. For example, dry vans weren’t showing up on time, forcing him to pick up the phone to find out what the hang-up was (and then waste even more time reporting the call outcome to his company’s field employees). “They just weren’t proactive,” says David. “Half of my week was dedicated to coordinating the deliveries.”

Turning the Tide

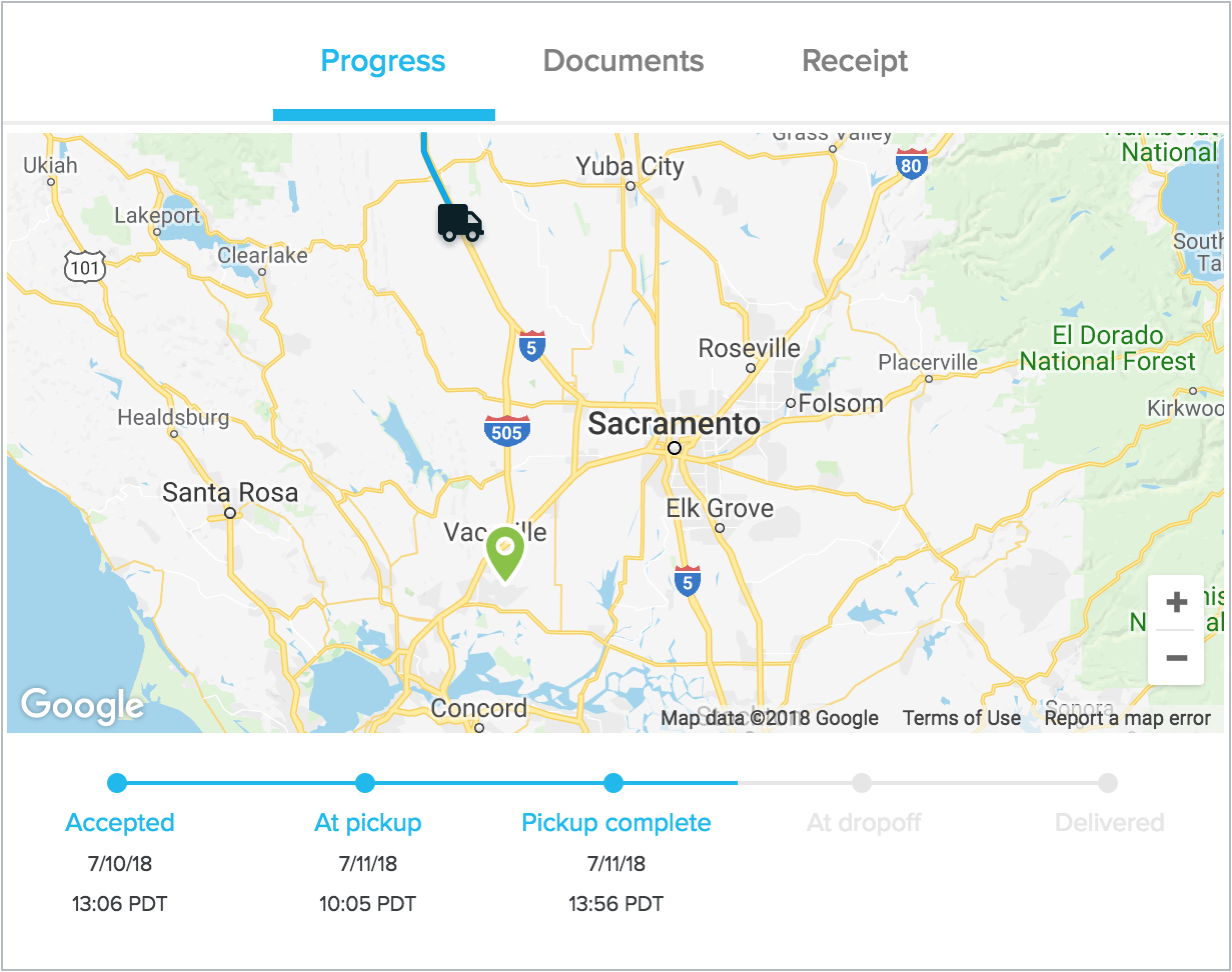

The tide turned when J.R. Butler began working with Convoy, which alerts David before the trucks are late. “When you’re shipping 10 trucks a week, something is inevitably going to go awry,” he says. “Convoy provided a much more reliable service, and in the cases where there looked like there may be delays, Convoy’s technology allowed them to proactively notify us.”

Using Convoy’s platform, David can easily see where trucks are, whether drivers are experiencing any delays, and accurate arrival times. He can then easily share that information with J.R. Butler’s receiving crew, which knows it can rely on the information provided. “They can just log in and see that a truck is 30 minutes away,” says David, “and plan accordingly.”

Initially, J.R. Butler’s field team was dead-set against using dry vans. “They were pushing back at just about at every angle they could,” says David, who adds that the field crew has since come full circle on that issue, thanks to Convoy. “I recently asked them what they’d pick if they could receive flatbeds or dry vans,” he says, “and they said, ‘dry vans, hands down.’ No questions asked.”

There’s also “no questions asked” about Convoy’s shipper-rating system, which allows drivers to rate and review facility drop-off and pick-up locations —a must-have in the current freight environment. “It’s pretty beneficial to be able to share our facility rating with my teams, and show them tangible results of us going above and beyond to accommodate drivers,” David notes.

Interested in learning more?

Fill out the form below to get in touch with our team to learn how we might partner to optimize your supply chain operations.