FreightWaves TV: Sustainability in Transportation with Convoy

Sustainability • Published on July 21, 2021

One of the unexpected outcomes of the pandemic was that the global supply chain was put under a microscope in terms of its breakdowns and inefficiencies — something which is not news to those who have been involved in the trucking industry for quite some time now.

Dan Lewis, CEO of Convoy was invited to talk shipping and sustainability with Danny Gomez, Managing Director, Financial and Emerging Markets at FreightWaves, for the inaugural episode of Net-Zero Carbon.

Some of Dan’s key takeaways follow.

What Inspired Dan To Form Convoy: His varied background from working at his family’s office supply business to a career at Amazon provided insight into the supply chain where he saw an opportunity to impact the business. His goal was to create efficiencies and reduce waste, particularly as it relates to the middle mile with heavy haul freight in terms of both shippers as well as the livelihood of truck drivers.

How The Pandemic Highlighted The Importance Of The Supply Chain: The world saw how incredibly critical and important the supply chain is for this country and how necessary it is when you are living at your home, not able to go out, and need things brought to you or your local grocery store. Even before then, however, Convoy was focusing on how truck drivers do such incredible work and why we need to build a system where they are treated fairly and respectfully and we can take care of them so they can thrive. This is what led the company to establish its mission of “transporting the world with endless capacity and zero waste.”

How Convoy Differs From A Digital Freight Broker: Convoy creates a more efficient trucking system using technology.

How Supply Chain Companies Can Get More Involved In Sustainability: Companies have so many opportunities to do the right thing, and they need to talk about it with their customers to create more awareness around sustainability as well as to keep truck drivers employed. As an organization gets bigger, they can organize things better and have their operation run more efficiently.

When It’s The Right Time To Begin Talking About Sustainability Initiatives: Dan believes it is never too early to start talking about it and start measuring sustainability initiatives. He strongly believes the way to get data is to imperfectly measure it at first. The difficulty in figuring out how to first measure it causes you to learn how to formalize it within your company and determine how to best measure it, and the more you work at it, the better you become until you can begin to share sustainability reports.

One Of The Biggest Issues In The Trucking Industry Which Needs To Be Addressed: Empty miles. By becoming better at reducing empty miles, less fuel is being burned per job and the driver doesn’t have to sit and idle while waiting for his appointment. There are a total of 175 billion miles being driven, 30-35% of those miles are empty or 62 million miles, which equates to 87 million metric tons of carbon emissions.

How The Trucking Industry Can Become More Sustainable Overall: If we can get carriers to apply a better system to reduce empty miles throughout the entire trucking system. As an industry, we should be invested in reducing fuel costs and reducing wasted hours so this becomes a win-win for everyone.

Misperception In The Industry: There is the perception that you have to sacrifice revenue to achieve sustainability goals. 85% of shippers say sustainability is really important to them and there have been some challenges overall, but Dan feels as an industry we have turned a corner. Sustainability goals help businesses to run more efficiently, make smarter procurement decisions, and then ultimately customers and partners are happy to work with them because they are working to be more sustainable.

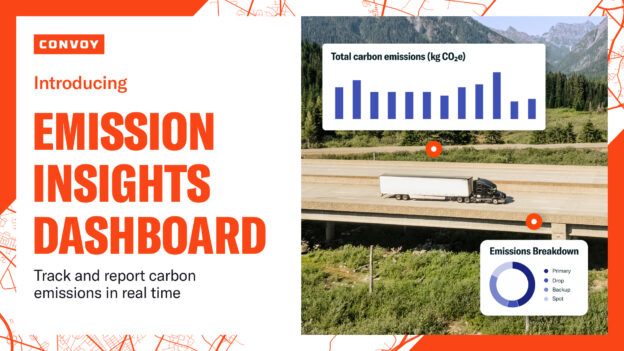

The Path Forward: Organizations really do want to be more sustainable. Convoy is trying to figure out how to give them the tools, data, information, and pathways to do that on the trucking and transportation side and how to measure it. Convoy gives all customers it works with a sustainability report to show the impact they are having by working with them. Everyone involved in the logistics and supply chain industry has a big responsibility to do everything they can to build efficiency into the system.

What Companies Can Do Now: First and foremost, ask providers you are working with what you can do to make your company more sustainable and reduce waste. Secondly, force yourself internally to measure your efforts. Make a goal as a company to come up with a metric to measure sustainability and assume you are not going to be perfect in the beginning, but it drives you to continue to make changes to get closer to something more impactful. Companies can also ask Convoy what they can do, including thinking about warehouse times, when you tender freight, appointment times, how to optimize live versus drop times, etc. In the near term, technology will look at different fuel options as we lead up to electric vehicles in the long term.

The Most Important Action A Company Can Take: Reduce the number of miles a truck has to work and reduce the time a truck is at a facility running idle or waiting for an appointment as a result of inefficient appointment times. We, as an industry, even need to look at truck stops and figure out more efficient ways to get power to that vehicle so it doesn’t have to sit there idling and using fuel.

What We Can Do As An Industry: Create standards around reporting the efficiency of networks. We need to measure the efficiency of systems, create incentives, and advertise the way we do rates and pricing to incorporate better efficiencies. It’s important for us to find a way to connect these efforts to the ultimate price people are paying and the money drivers earn. We also need to give benefits/incentives to companies who create efficiencies in the system as these drive behaviors which would align with a more sustainable network.

How We Need To View The Environment: We need to realize the environment is also a customer that pays us in different ways. Extreme weather is not good for the supply chain so consider the impact our industry has on the climate. If we reduce emissions, the environment pays us with fewer storms, cleaner air to breathe, better food we can grow, etc. The environment is a customer of ours and we must do our part to make sure we are taking care of this customer.

TRANSCRIPTION

Danny Gomez: Welcome to Net-Zero, a show where we focus on information insights and inspiration sustainability in transportation. I’m your host, Danny Gomez, and today I’m joined by Dan Lewis, co-founder and CEO of Convey. Dan, thanks for joining us today.

Dan Lewis: Thanks, Danny. Its awesome to be on here with you.

Danny: So, I want to jump in really quick. We have a lot to cover in a little bit amount of time. I’d like to go back a little bit. You know, you’ve got a really interesting background. You know, you graduated from Yale with a degree in cognitive science, you have a pretty well studded resume. You’ve worked at Amazon, Google, Microsoft, and then you decided to jump into transportation. Could you take us a back a little bit on that journey of, you know, just the personal story of kind of where you came from and how you got to that decision to jump in and start your own company.

Dan: Yeah, so I grew up in Seattle. I’m actually one of five kids. At the time, I would have never thought that it would have impacted future roles that I had but growing up my job was to work for our family office supply distribution company. So that was everything from doing accounts receivable, calling companies and saying you guys have to pay us, or packing trucks and building furniture and doing delivery routes, straight vans, around the Seattle area delivering stuff to companies. Fast forward a bunch, I went to Yale, that was extremely fortuitous. That was a great experience in my life, and I had, you know, left Washington, the west coast for the first time, lived pretty far away. Went to Chile actually. Spent my junior year abroad and the reason that was impactful is that ended up leading me to go later do some work with [2:00] the Panama Canal in Mexico and Panama and ultimately went and worked for an airline in Spain on a project doing a lot of maintenance repair and overhaul work and parts distribution work. So little pieces of supply chain exposure and experience that I picked up along the way, then got into tech when I moved back to Seattle, where I’m from and had a great experience learning about how to build software, consumer products, did a ton of work in machine learning, artificial intelligence, and that was what led me to Google. The company that I was with was acquired. And ultimately it was Amazon. And at the time, for a while, Amazon had been differentiating itself through supply chain innovation and through rapid delivery and consumers were getting used to this idea of very fast delivery and it was changing behavior. If you wait until there is one to two days left and you’re a subscriber to Amazon Prime, you’re probably going to buy there because you know its going to be delivered in one to two days. So, you can procrastinate and be lazy and order from your house and get it in a day. That was kind of a pretty remarkable change. A lot of companies started to take notice of that and respond. I was at Amazon, I saw an opportunity to go and back in the supply chain, I felt like there was a big opportunity there. I didn’t realize how much opportunity there was to create efficiencies and reduce waste. And so, I quit Amazon in early 2015 to go explore some ideas and I spent…and those ideas were going to be in transformation supply chain because some of the investors I had spoken with, some of the opportunities I had seen at Amazon and other companies just seemed like that space was really exploding. I looked around there were so many companies doing last mile delivery, or reverse logistics, or things like that and parcel delivery. But there weren’t a lot of companies focusing on heavy haul freight for the middle mile. And after a bunch of conversations, I realized that, you know, that was an area that had [4:00] extreme fragmentation, it was pretty much off the grid at that point, pretty opaque from a data perspective, and, you know, there were two big sustainability opportunities which were directly tied to the business model. One was reducing waste from an environmental perspective, reducing carbon emissions, reducing, you know, time center burning fuel at a facility or empty miles being driven. And the other one was related to the livelihood of truck drivers and kind of essential workers which in 2020 I think the supply chain was highlighted as being so incredibly critical and important for this country. And so many people recognized how, you know, necessary it is. Everything from all the PPE to the vaccines, to just food when you are living at your home and not being able to go out, having someone bring that to you, or your local grocery store. So, even before that, you know, we were thinking about, man, truck drivers do so much incredibly difficult work, we need to create a system where they get treated really fairly and respectfully so they can thrive. So those are the two areas, the sustainability and kind of taking care of truck drivers that are directly tied to our business model and if we’re successful in doing those two things, we’re creating an extremely valuable business at the same time.

Danny: That’s interesting because there is a lot of companies who are adding in sustainability now. Maybe because they want to, or they feel like they are being forced to. But for you it was part of the beginning. Was it part of your going out and finding investors in, you know, that value rung true to them? It sounds like, right?

Dan: Yeah, the stated mission of the company is to transport the world with endless capacity and zero waste. And that sort of has been the idea of what we can go do since we started. And every shipper I’ve ever talked to says, ‘Look, we’d love to have trucks when we need them, where we need them, efficiently, reliably, at a fair price, with transparency and visibility.’ And in order to get that, they…anyway. There is a lot of waste that goes into the system to get that level of service. So how do you give that level [6:00] of service while also reducing waste at the same time,

Danny: Alright, so, just for a moment, for those who may not be super familiar with Convoy. Can you just very quickly describe exactly what Convoy does and the value it provides?

Dan: Yeah. We make T-shirts. Sustainable T-shirts. Yeah, Convoy provides trucking services, full truck load services. So, you know, and we work on one side with small owner operators, small carriers that use the Convoy platform to find work and complete work and then on the other side of our marketplace are companies that ship truckload freight. And so, we’re moving truckload freight all across the United States. We do drive in, refrigerated freight, we do, you know, live load, unload. We have a trailer pull, a universal trailer pull. Really innovative trailer pull concept we’ve built for, you know, pre-loaded trailers and dropping hook work. And sort of expanding on that, we’ve now built some TMS offerings for small shippers and we have a bunch of services we provide for carriers along the way that are part of our network. But ultimately, we’re providing trucking services for shippers and work for small carriers and owner/operators.

Danny: That’s very helpful. And you very intentionally say that you are a freight network and not a digital freight broker. I assume that those choice of words are meaningful to you and your business.

Dan: Yeah, that is intentional and that is something that we started talking about a year or two ago. And, you know, the ideas that the digital broker concept, which in part applies to what we do, but it tends to relate to building technologies and tools that allow brokers to be more efficient.

Danny: Right.

Dan: And what we’re building is a system where each of these different trucking companies and truck drivers is plugged into our system and we have a requirement to use our technology, so we have really high use and adoptive technology across the board. And so, we do a lot of network planning. We think about how do we then take this freight and make it optimal. [8:00] How do we find the optimal round trip, we automate backhaul recommendations to reduce empty miles, and we think a lot of about network planning. We have a trailer pull, we kind of optimized around the system. And we think really long term with our customers. So, it’s about using technology to create a more efficient system of appointment times, trailer utilization, you know, rolling assets and knowing what they are at what point and kind of brining that all together using technology and machine learning to optimize, while still providing all the customer support along the way. That’s a requirement. But behind the scenes, we are doing a lot of work to try to reduce waste and optimize systems. That’s more of a network play when you think about the level of planning that goes into that.

Danny: Sure, and in everything you’re saying, you hear efficiency and reducing waste and even as you’re forming the company. Obviously, a lot has changed in the recent years whether it was because of Covid, and people are more aware or there is just more talk about ESG and sustainability. It’s been part of your DNA since you started. You did make a change and you had Jennifer Wong come up as the head of sustainability, did something change? Surely there was more attention around it. I think helpful for people who are listening is one, what brought you to that decision point to bring it to the next level, and as people look internally whether it is your peers or other people in the industry, when they’re looking to source of find talent internally or externally to fill these types of roles, you know, it’s a fairly new discipline, right? How do you go about identifying the right people internally to help you lead on this charge?

Dan: Yeah, it is a relatively new discipline. I remember a friend of mine in Seattle became the sustainability director manager at Brooks Sports, maybe eight, nine years ago, his name is Dave Camp and I remember thinking, oh, that’s a job. That’s interesting, that’s kind of cool. Like, it’s a job, you can be the sustainability person. And Brooks has [10:00] been a leader in this area. And that’s the first time I ever even heard about that job. So I think the reason we decided it was worth it is we were getting to the point where there were so many opportunities to not only do the right thing internally and focus on the sustainability of how we run our business, but we were getting to the point where we had the data and the information to start to talk about a lot more in highly relevant ways with our customers, help them see opportunities to build sustainability into their business, talk to truck drivers about how they can actually improve their earnings by acting more sustainability and partnering with us on some of these initiatives, and kind of the scope of impact that we could have was significant. So, it made a lot of sense to have somebody come in and full-time kind of run that and tell that story and drive those actions. And, you know, before that, we were doing a lot of these things and it was part of the company and everybody kind of had a hand in doing it, but one thing I just learned as a first time CEO, as you get bigger, everyone chipping in and doing something is still great but you can actually organize that energy so much better when you have somebody kind of like driving it directly, and a single threaded owner as we talk about for that particular thing. So, Jennifer graciously stepped up and she is super passionate about it, and she took on a role and she has done an incredible job of helping us achieve this. And the other thing that I think I’ve learned that is worth sharing is its never too early to start talking about it and measuring your sustainability outcomes. One of the things that I was nervous about was when we first started, we actually had internally for Convoy, along with our revenue goals, our shipment growth goals, our margin goals, we had a reduce empty miles goal that was a stated company goal well before we ever talked about it publicly, and we were really bad at measuring it. We didn’t even know how to measure it exactly. We just said, “Look, we’re going to make this goal for the company, we’re going to talk about it every month, we’re going to figure out how to measure it.” So, we tried to measure it, we got better and better, we tested this and did this. [12:00] And several years later, we were at the point where we actually knew how to measure it well enough, and we built a tools and systems to measure well enough that we could actually release our sustainability report and talk about it. But that wasn’t just overnight, and I think sometimes people think, I’ve got to wait until I know exactly how to measure this, until I have all the perfect data to start doing it. And you just wait. But actually, the way you get to that data, is imperfectly measuring it. Doing it, you know, maybe in a way you’d be embarrassed to share, but that causes you to learn a bunch and figure it out and people think about and they’re like, oh, I can do this thing and then they have this idea, and it goes forward. So, its never too early to start formalizing it within your company and talking about it and measuring it. Even if its imperfect. I think that’s really important.

Danny: Yeah, I think when you say internally is probably the good first step, right. I think what we see is there is a tendency for people to get out in the public, they want to make a headline and they’ll make commitments to being net zero by a date or reducing or being 100% EV by a certain date. You know, I was talking to someone recently, a consultant, saying, “We went into a company and said, ‘Hey, look, that wasn’t the best approach to sustainability. There was other things you could have been doing.’ And I think in reading your sustainability report, what I find really inspiring is the data that you have behind the things you’re achieving. And you guys have been hyper focused on efficiency and empty miles. Talk a little bit about what you’re doing there, and I think extending, even on your website, right. Its not just talking your own book, it’s a little bit of a challenge of saying, “Hey, look, if we did this as an industry, this is the types of savings we would see.” Talk a little bit about the empty mile focus for you.

Dan: Yeah, and that obviously directly relates to less fuel being burned per job and then its empty miles and its appointment times. Like, having the right times…at the facilities, you don’t sit there and idle and burn fuel. So, we look at all the ways unnecessary fuel is burnt. We estimate that about and looking at some of the Bureau of Transportation statistics and things like that, [14:00] some of these sources, but 175 billion miles are driven truckload every year. About 30, 35% is empty. In our network, its 35, I think 36 on account of the medium to small carriers, and so, we estimate about 61 billion of those miles are driven empty. And that actually results in about 87 million metric tons of carbon released in the atmosphere every year. We’ve run a bunch of experience to look at what happens to empty miles when carriers adopt our automatic reloads program and systems that we build to try to create kind of perpetual optimized trips and reduce empty miles between jobs. And we found that when we do that correctly, we can get those carriers down to about 19%, 18, 19% empty miles. Which is really remarkable for a pretty fragmented system of, you know, smaller companies. This considers all of their miles. And so, if we can apply that system to the entire, you know, community of trucking and truck drivers, you could reduce 40 million metric tons of carbon, which is equivalent to over 10 million, you know, the emissions of 10 million passenger cars every year. And so, you know, that’s the top level and those are big numbers, that’s the high level. There is probably a million details underneath that we need to figure out but that helps us set the goal post for kind of the opportunity size, it makes it really clear that we, as an industry, should invest in this. And what’s great is if we do that, we also reduce a bunch of costs in the system. Truck drivers spend less money on fuel, they’re spending fewer hours getting their jobs done because they have fewer empty miles legs, and the industry actually runs more efficiently, and things probably get there faster too. So, it’s a win, win. And we’re really fortunate that, you know, in trucking it’s a very clear win, win. We can go after that with all of our energy.

Danny: I think, you know, that messaging that you talked about earlier in kind of marrying these, you know, you’re talking to owner operators and you’re trying to make them run as efficiently as possible. I think there is this, I don’t know, [16:00] this perception that you have to sacrifice revenue if you’re going to achieve some sort of sustainability goals. If you’re going to be operating in a more sustainable way. How do you guys message that, you’re providing data, you obviously have the information to show them but I’m sure there is a healthy amount of skepticism that comes with that type of messaging and how do you get through those walls?

Dan: Yeah. First off, we’ve done some surveys and 85% of the shippers that we talk to say that sustainability is really important to them as an organization. And most the Fortune500 companies that we work with have sustainability goals, for example. So, there are some challenges around motivation but actually at this point I think we’ve turned a corner for a bit where a lot of companies know this is important and they can see that when they act more responsibly and sustainably, they run their businesses more efficiently. They’re smarter about the procurement decisions they make, and their customers and partners are happy to work them. And so, just first and foremost, I think that, you know, people really do want this now and they’re caring about it. So, what we’re trying to figure out is how do we give them the tools, data, information, and you know, pathway to do that on the transportation trucking side. And then to measure it and say we give all of our customers a sustainability report that shows the impact that they’re having when they work with Convoy and using our various programs. And I think that’s either all the way rolled out or is rolling out. And then, you know, if there are questions or concerns, I think it really just comes down to, again, what are their customers care about. Ultimately, they’re serving their customers, so their customers care about sustainability. And its generally better for their business if they partner with us on reducing waste in the system because that can actually reduce their cost. So, they can lower their cost by working on programs like this. So, I feel like in the logistics and supply chain space, we have a big responsibility [18:00] in the greater scheme of things to do our part and push pretty hard here because it actually accrues very nicely in the business as well. Its very complimentary and so, aligned I mean. So, I think we should be doing everything that we can in the space to reduce waste and build efficiency in the system.

Danny: Its interesting that what you guys have highlighted, and this is a question I get all the time, what can we do now. Right. And there is a lot of focus on EV and, you know, with EV there’s the demand side which is picking up and then there is going to be constraints on the supply and the infrastructure side and people want to know what they can do now. So, I think it’s very good that you guys have highlighted a problem in the industry that can be addressed now through technology but not in a way that is overly burdensome from an investment perspective, right. This is opportunities that are out there, and it doesn’t sound like there needs to be a huge investment made whether its working with you or even doing it within their own fleet to make things more efficient. I’d like to understand two things. One, how do you scale that model out beyond just Convoy, right. How do you push that across the industry? And then, two, what other things are you guys thinking about that are around the corner that may be a little bit heavier handed in terms of investments and technology?

Dan: Yeah, everything you said kind of makes a lot of sense on where things are going, and I agree. Electric vehicles are super impressive and they’re going to make a really big impact here and its going to take some time to roll out the infrastructure and the equipment, obviously, to do that. So that’s quite a ways out I think in terms of the turnover in the industry on that. So, things people can do now, one I would say is when you are working with your providers, ask them to provide you with information and data or recommendations for how you can be more sustainable. The people that are providing logistics services or transportation services for you are thinking all the time about how they can reduce waste for their [20:00] own business because it is generally better for them. Ask them what you can do to actually make their lives easier and help them reduce waste. You know, come and talk to Convoy. We have Jennifer, we have other people here who have a lot of experience in thinking about sustainable networks and programs, and we’re happy to talk to companies about how they can do that themselves, to give advice to kind of look at people’s programs and we learn a lot by doing that as well. So, I think asking for data and feedback and then, you know, if we are able to do that on the truckload side, I think those are both really important. I would also say that, you know, internally, its just something to try to force yourself to measure. I say force yourself as in, it might not be obvious in how to do it but, you know, present that. Say, let’s make a goal as a company in the next quarter, the next two quarters, we’re going to come up with a metric to use to measure the most direct way that we are impacting sustainability. Let’s track it, we’ll do the best we can to track it and we’ll get better and better over time. And assume you’re not going to be perfect at the beginning. I think that’s a really good way to get started as well, and any companies that work with Convoy are looking at truckload, please come ask us, like how could we think about our warehouse operations, how could we think about our appointment times, how could we think about when we tender freight, and kind of the network that we run and how we optimize maybe live or a number of things, there is a lot of room for improvement and efficiency on those things that reduces waste and that’s kind of the bread and butter of what we’re doing.

Danny: Aside from EV, what is some near-term technologies that you think, is it alternative fuels, is there something in the medium term that we should be looking at as well?

Dan: So, I think different fuels and leading to EV in the future I think is part of this. I know there are other systems. There have been systems around, you know, Peloton for how different trucks can draft down the highway together and, you know, reduce fuel burn. But I think honestly, [22:00] the most impactful thing that we’re going to see over the next five to ten years, until some of these alternative systems are there, is simply [24:00] reducing the number of miles a truck has to run to do the same amount of work and reducing the time the truck has to run at facilities idling. And I think, or kind of waiting for an appointment. Like, inefficient appointment times that cause the truck to lose hours or spend a lot of time waiting. And another one we’ve been looking into, you know, at truck stops, are there more efficient ways to provide power to the trucks versus them running and being idle or in different places. So, there is some other ways we can think about getting power to that vehicle when it doesn’t need to run and burn fuel to achieve that power. But I think honestly, its about efficiency. That’s, you know, 10X, most of the opportunities in the next few years.

Danny: What do you hope to see, and you mentioned it a second ago, you’re happy to talk, you’re happy to share your ideas. This is a unique problem, right. Its not one that Convoy can solve on its own. We’re better together than alone mentality, right. So how do we as an industry come together, what do you want to see? Is it associations, you know, there is obviously some lobbying efforts, but you know, just in general, how can we come together to solve this?

Dan: I think that, so there are a few things. One is when you’re building a platform, they can really optimize these things. Finding ways to open it up and let other people plan their system using some of these best-in-class platforms. We’re working on some things like that, and we think that that can be really valuable because there is a lot of companies that don’t know how to build this stuff and don’t have the engineers, technologists, data scientists on staff. The companies that are fortunate enough to have that should build these solutions and kind of allow other people to plug into those platforms. So that’s one thing that we believe in, kind of open platforms that allow companies to do that. And we’re going to be doing some work there in the future. I think, another one is simply, you mentioned, you know, maybe some of these companies setting goals against it or going and getting input, I think that one thing we can do, I’ve mentioned this several times now, to share as an industry is to actually create standards around reporting on efficiencies of networks. So, our customers think a lot about, you know, on time performance and are we, you know, are we fulfilling all the jobs that we are going to do in a given lane and how much of their needs are we meeting, etc. There are other things around how you actually measure the efficiency of the system and creating incentives so that if we operate more efficiently, and our customers partner with us to do that, they can save money. So, advancing the way we do rates and pricing to really incorporate efficiency would be I think a way to win. And I think it would right now, you know, companies that are super-efficient don’t always realize all those benefits through lower prices and companies that are very inefficient, don’t realize all those costs. They’re often shared across all the providers. I would love to find a way to, you know, connect those efforts with the ultimate price somebody is paying and give the benefits to companies that are creating efficiencies in the system for everybody. That actually would drive it because, you know, money talks and money drives behavior. So, if we could find ways to align those better, I think behaviors would change to align with this better as well.

Danny: Yeah, I think you’re right. Market, everyone loves market-based activity so that would be great to see that, and we’ve talked about that here at Freight Waves as well. You know, how does emissions show up in pricing and I think that you’re right. I think that probably is around the corner. At Convoy, you guys are working with shippers and carriers. How does the environment fit into that picture?

Dan: Yeah, that’s a great question. So, shippers and carriers of the customers that operate as part of our marketplace, I honestly think the environment is also a customer. And I’m not just [26:00] saying that it pays us in a bunch of different ways. We’ve seen extreme weather pick up across the country. Not having extreme weather is really good for the supply chain. And so, if you think about, you know, the environment having a stable, like, system and a stable rhythm and operating within like normal bounds, that’s really good for the ability for trucks to drive. Fewer hurricanes, fewer extreme winter storms, fewer extreme heatwaves, so I think the environment pays us that way. And honestly, like, we’re breathing fresh clean air right now and, you know, we can operate our businesses with all these benefits that come from the environment. The food it produces, you know, all the materials it produces for us, the water that we get to drink. So many things, its pragmatic to think the environment is a customer of ours and it’s paying us every day in so many different ways and we need to do our part to make sure that we are taking care of it along the way.

Danny: Dan, this has been super great. I would love to have you back. We just kind of scratched the surface. You guys are doing amazing things. For those that aren’t following you, they should. You guys are putting out a lot of great content, your sustainability report as well as the surveys that you’re doing so I recommend people get plugged. I really appreciate your time today and hopefully we can have you back.

Dan: Absolutely, I’d love to come back some time. Thanks, Danny.

Danny: Thank you.